NEWS

The Importance of Using Silicon Metal in Aluminum Wheel Casting

The aluminum wheel casting industry is a vital part of the automotive and aerospace industries. Aluminum wheels are widely used in these industries due to their lightweight, corrosion-resistant properties, and high strength. Silicon metal is one of the key components used in the production of aluminum wheels. Its addition to aluminum alloys improves their mechanical properties, making them ideal for use in various applications.

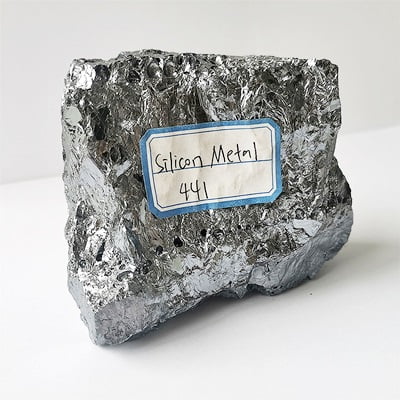

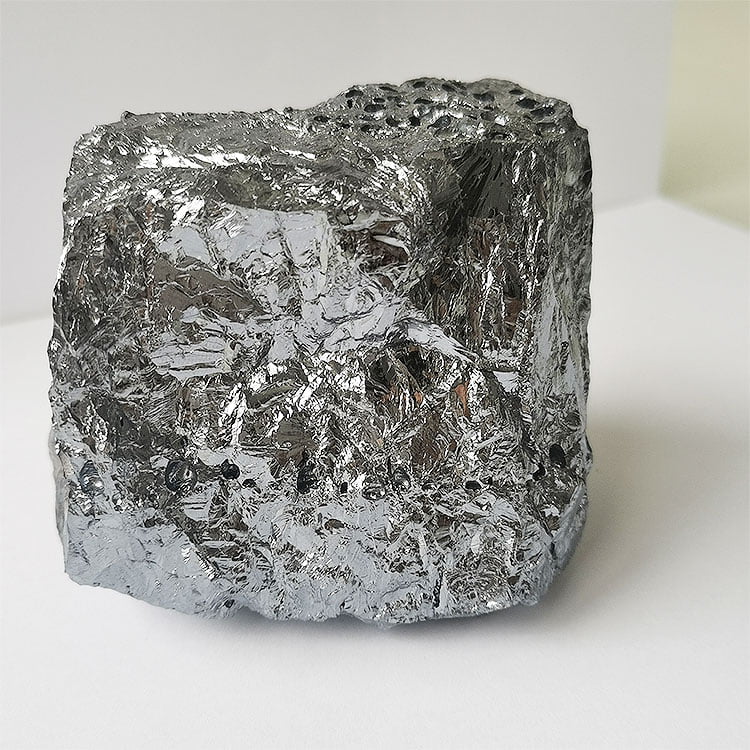

Silicon metal is a high-purity grade of silicon that is produced through a complex process that involves the reduction of silica with carbon in an electric arc furnace. The resulting silicon metal contains approximately 99% silicon and trace amounts of other elements, such as iron, aluminum, and calcium. The purity and composition of silicon metal can be customized to meet the specific requirements of different applications.

One of the most significant applications of silicon metal in the aluminum wheel casting industry is in the production of aluminum-silicon alloys. These alloys contain varying amounts of silicon, depending on the specific application and the desired properties of the alloy. The addition of silicon to aluminum alloys improves their mechanical properties, such as strength, hardness, and wear resistance.

The production process of aluminum-silicon alloys involves several stages, including melting, casting, heat treatment, and finishing. Silicon metal is added to the molten aluminum during the melting stage to form the desired alloy composition. The alloy is then cast into molds to form the wheel shape. The cast wheels are then heat-treated to improve their mechanical properties and undergo various finishing processes, such as machining and polishing.

One of the key advantages of using silicon metal in aluminum-silicon alloys is its ability to improve the castability of the alloy. This means that the alloy can be cast into complex shapes with high accuracy and minimal defects. This is particularly important in the production of automotive wheels, where design and aesthetics play a significant role.

Another advantage of using silicon metal in aluminum-silicon alloys is its ability to improve the wear resistance of the alloy. This means that the alloy can withstand harsh environments and resist damage from abrasion and corrosion. This is particularly important in the aerospace industry, where wheels are exposed to extreme conditions during takeoff and landing.

Silicon metal is also used in the production of other aluminum alloys used in the automotive and aerospace industries. For example, it is used in the production of aluminum-lithium alloys, which are lightweight and have excellent fatigue resistance. These alloys are widely used in aerospace applications, such as aircraft fuselages and wings.

In addition to its use in aluminum alloys, silicon metal is also used in other applications in the automotive and aerospace industries. For example, it is used in the production of brake pads, where it improves the wear resistance and thermal stability of the pads. It is also used in engine components, such as pistons and cylinder heads, where it improves the strength and thermal conductivity of the components.

Silicon metal plays a critical role in the aluminum wheel casting industry and other applications in the automotive and aerospace industries. Its addition to aluminum alloys improves their mechanical properties, making them ideal for use in various applications. Silicon metal also improves the castability and wear resistance of aluminum alloys, allowing for complex shapes with high accuracy and minimal defects. The use of silicon metal in other applications, such as brake pads and engine components, further highlights its importance in these industries.

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China