NEWS

Factors You Should Consider When Purchasing Silicon Metal

When purchasing silicon metal, there are several factors to consider to ensure that you are getting a high-quality product:

Purity: The purity of silicon metal is one of the most critical factors to consider. High-quality silicon metal should have a purity level of at least 99.5%. The higher the purity level, the better the quality of the material.

Size: Silicon metal is available in different sizes, and you should choose the appropriate size for your specific application. The size of silicon metal is typically specified in terms of mesh size or particle size distribution.

Chemical composition: The chemical composition of silicon metal can affect its properties and performance. You should verify that the chemical composition of the material meets your specific requirements.

Packaging: The packaging of silicon metal should be suitable for the material to prevent contamination and damage during transportation and storage.

Supplier reputation: The reputation of the supplier is an important consideration when purchasing silicon metal. Choose a reputable supplier with a history of providing high-quality products and good customer service.

Price: Price is also a consideration when purchasing silicon metal, but it should not be the only factor. Choose a supplier that offers competitive pricing while providing high-quality products and reliable customer service.

In summary, when purchasing silicon metal, you should consider its purity, size, chemical composition, packaging, supplier reputation, and price to ensure that you are getting a high-quality product that meets your specific requirements.

You May Like to Learn More...

Contact Us

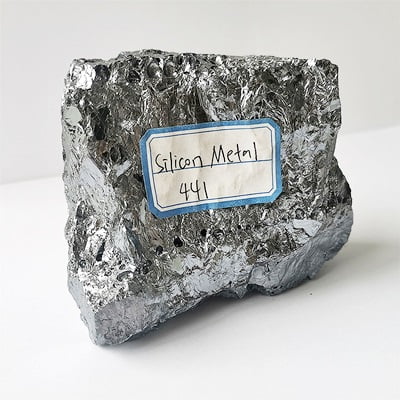

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China