NEWS

Factors Affecting the Particle Size and Absorption Rate of Silicon Metal

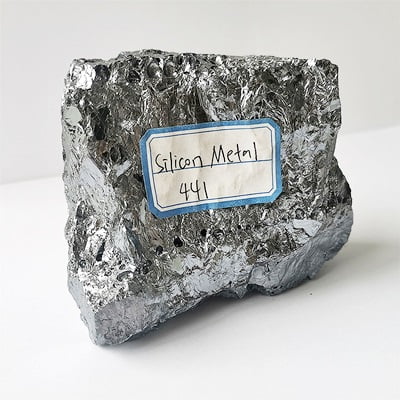

The absorption rate of silicon metal is influenced by various factors related to the production process. Silicon metal is primarily used in the production of silicone compounds, which are used in a wide range of industries, including automotive, construction, and electronics. The absorption rate of silicon metal refers to the rate at which it reacts with other materials to form silicon compounds.

First of all, Oxygenated silicon metal may have a higher absorption rate compared to non-oxygenated silicon metal due to the presence of oxygen in the material. Oxygen can react with silicon to form silicon dioxide (SiO2), which is a common component of many types of glass and ceramic materials.

During the production process, oxygen can be introduced into the silicon metal through the use of raw materials or through exposure to air. The presence of oxygen in the material can increase its reactivity and enhance its absorption rate.

One of the key factors that impact the absorption rate of silicon metal is its purity. High purity silicon metal is more reactive and has a higher absorption rate than impure silicon metal. Impurities such as iron, aluminum, and calcium can reduce the reactivity of silicon metal and lower its absorption rate. Therefore, it is important for silicon metal producers to maintain high levels of purity in their products.

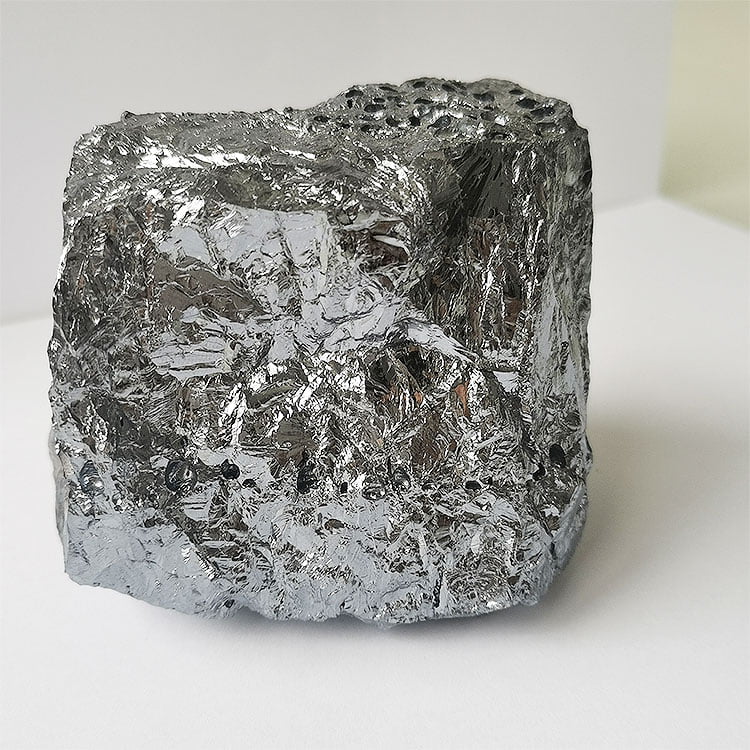

Another factor that can impact the absorption rate of silicon metal is the particle size of the material. Finer particles have a larger surface area and are more reactive than larger particles. Therefore, silicon metal with a smaller particle size will have a higher absorption rate than larger particles.

The temperature and pressure conditions during the production process can also affect the absorption rate of silicon metal. Higher temperatures and pressures can increase the reactivity of silicon metal and enhance its absorption rate. However, it is important to maintain safe operating conditions during the production process to prevent accidents.

The type of furnace used in the production process can also impact the absorption rate of silicon metal. Electric arc furnaces are commonly used for silicon metal production and can produce high-quality silicon metal with a high absorption rate. However, other types of furnaces such as submerged arc furnaces and plasma furnaces can also be used depending on the specific requirements of the application.

Finally, the chemical composition of the materials used in the production process can impact the absorption rate of silicon metal. For example, the addition of certain elements such as boron or phosphorus can enhance the reactivity of silicon metal and increase its absorption rate.

In conclusion, the absorption rate of silicon metal is influenced by various factors related to the production process. Maintaining high levels of purity, particle size, and safe operating conditions can enhance the absorption rate of silicon metal. The type of furnace and chemical composition of the materials used can also impact the absorption rate. Understanding these factors can help silicon metal producers optimize their processes and produce high-quality products with a high absorption rate.

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China