NEWS

The Application and Advantage of Electrolytic Manganese Metal Flakes

Silicon metal plays a crucial role in the production of aluminum ingots, offering a range of benefits that contribute to the overall quality and performance of the final product. In this article, we will explore how silicon metal works and its functions in the aluminum ingot manufacturing process.

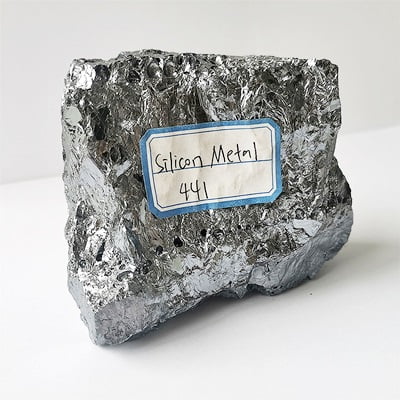

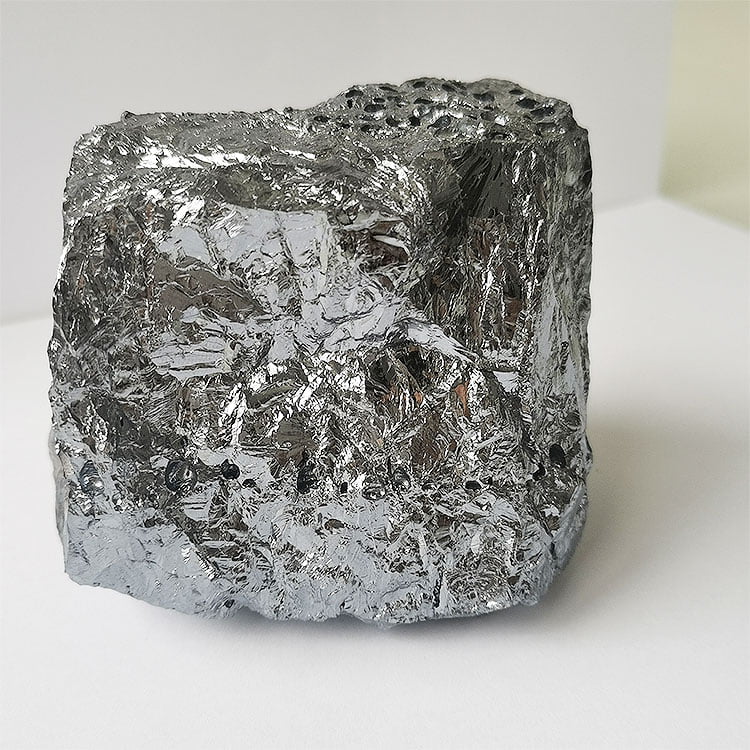

Silicon metal is a key additive used in the production of aluminum ingots. It is derived from silica, a compound found abundantly in nature. Through a complex process known as smelting, silica is transformed into silicon metal, which is then blended with aluminum to create alloys.

One of the primary functions of silicon metal in aluminum ingots is to enhance their strength and durability. When silicon is added to aluminum, it forms a solid solution, strengthening the metal matrix. This results in improved mechanical properties, making the aluminum ingots more resistant to deformation and wear.

Silicon metal also imparts improved heat resistance to aluminum ingots. The addition of silicon increases the melting temperature of the alloy, allowing it to withstand higher temperatures without losing its structural integrity. This property is particularly advantageous in applications where the aluminum ingots are exposed to elevated temperatures, such as in the automotive and aerospace industries.

Another crucial function of silicon metal is its ability to reduce oxidation in aluminum ingots. When exposed to air, aluminum has a tendency to oxidize, forming a thin layer of oxide on its surface. This oxide layer can negatively impact the mechanical properties of the metal. However, by incorporating silicon into the alloy, the formation of the oxide layer is minimized, thereby preserving the integrity and quality of the aluminum ingots.

Silicon metal also improves the fluidity and castability of aluminum during the ingot production process. The addition of silicon reduces the viscosity of the molten aluminum, allowing it to flow more easily into molds and intricate shapes. This property is highly beneficial in industries that require precise casting, such as the manufacturing of automotive components and electrical equipment.

Silicon metal is an essential component in the production of aluminum ingots, offering a range of functions that enhance the quality and performance of the final product. From increasing strength and durability to improving heat resistance and reducing oxidation, silicon metal plays a vital role in the aluminum industry. Its ability to enhance fluidity and castability further adds to its value. As the demand for lightweight and high-performance materials continues to grow, the importance of silicon metal in aluminum ingot production remains undeniable.

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China