NEWS

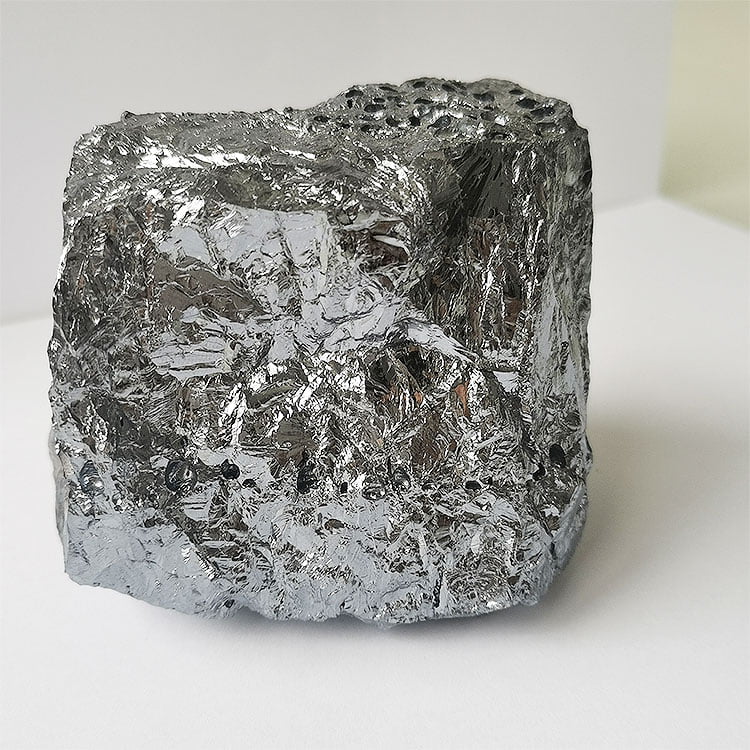

Silicon Metal: The Key to High-Strength and Wear-Resistant Aluminum Alloys for Automotive Manufacturing

Silicon metal is a preferred choice for the automotive industry for engine blocks, cylinder heads, and other parts because of its ability to improve the mechanical properties of aluminum alloys used in the manufacturing of these parts. The addition of silicon metal to aluminum alloys creates an aluminum-silicon alloy, which has several advantages over pure aluminum in terms of strength, wear resistance, and thermal properties.

One of the main reasons why silicon metal is good for the automotive industry is its ability to improve the strength of aluminum alloys. Engine blocks and cylinder heads are subjected to high levels of stress and pressure, and they need to be strong enough to withstand these forces without cracking or failing. Aluminum-silicon alloys, which are formed by adding silicon metal to aluminum, have higher strength than pure aluminum, making them an ideal material for these applications.

In addition, the wear resistance of aluminum-silicon alloys is also improved compared to pure aluminum. Engine blocks and cylinder heads are subjected to friction and wear, which can cause damage and reduce the performance of the engine. The use of aluminum-silicon alloys, which are more wear-resistant than pure aluminum, can help to extend the life of these components and improve the overall performance of the engine.

Furthermore, the thermal properties of aluminum-silicon alloys are also improved compared to pure aluminum. Engine blocks and cylinder heads need to dissipate heat effectively to prevent overheating and engine failure. The use of aluminum-silicon alloys, which have better thermal conductivity than pure aluminum, can help to improve the cooling efficiency of these components, ensuring that the engine runs at a safe temperature.

In summary, the use of silicon metal in the automotive industry for engine blocks, cylinder heads, and other parts offers several advantages, including improved strength, wear resistance, and thermal properties. By using aluminum-silicon alloys formed with silicon metal, manufacturers can create high-performance components that can withstand the rigors of automotive applications, ensuring that engines are reliable and efficient.

You May Like to Learn More...

Contact Us

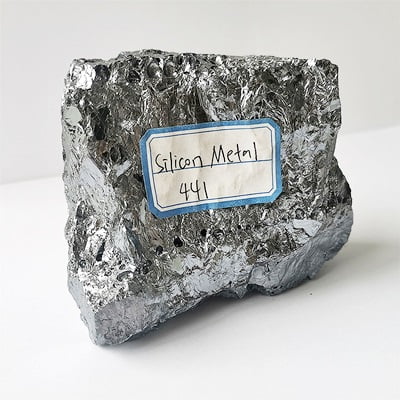

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China