NEWS

The Importance of Deoxidizing Molten Steel

In the oxidation period, in order to remove carbon, phosphorus, gas and inclusions in the metal, oxygen must be supplied to the molten pool to cause the molten pool to boil. In this way, a certain amount of dissolved oxygen is also contained in the metal, and the oxygen remaining in the steel will greatly affect the quality of the steel. One of the characteristics of electric arc furnace steelmaking is that the atmosphere in the furnace can be controlled, and reducing slag can be produced during the reduction period.

The main task to be completed during the reduction period is deoxidation, followed by desulfurization; at the same time, the composition and alloying of the molten steel must be adjusted according to the specifications of the finished steel, and the temperature of the molten steel must be adjusted to ensure normal pouring after tapping.

It is mainly dissolved in the molten metal in the form of oxygen (or dispersed as FeO), and it plays an important role in oxidation. But for the quality of finished steel, oxygen is a harmful element, and it must be reduced to a minimum during the reduction period. The impact of oxygen on the quality of steel is manifested in:

First, due to the huge difference in solubility between molten steel and steel ingots, during the electric furnace steelmaking process, the oxygen content in the metal is generally 0.01-0.06% at the end of oxidation, while the solubility of oxygen in the solidified steel ingot is only 0.002-0.003 %). Therefore, when the molten steel with incomplete deoxidation is solidified in the mold, as the solubility decreases, oxygen is precipitated from the steel in the form of FeO, which increases the oxygen content in the unsolidified molten steel, and CO gas is generated when it exceeds the balance of carbon. The generated gas stays in the steel ingot to form pores, bubbles and porosity, which will cause the steel ingot to crack during processing.

Second, during the solidification process of molten steel, FeO and Fe form a eutectic, and its melting point is lower than the eutectic temperature of Fe and FeS. It precipitates on the grain boundary in the form of a thin film, and melts first at the temperature of hot working, often causing the billet to crack.

Third, FeO reacts with other elements in steel such as Al, Ti, Si, Mn, etc. to form deoxidized products, that is, endogenous inclusions in steel The higher the molten steel content, the more endogenous inclusions are formed. They generally have small particles and are unevenly distributed in the steel. Non-metallic inclusions in steel are very harmful to the quality of steel.

In addition to the deoxidation products remaining in the molten steel, the sources of oxide inclusions in the electric furnace include oxides brought in by iron alloys. The molten steel scours and corrodes the refractory material in the tapping and pouring project, which may cause a part of the refractory material to remain in the molten steel.

The inclusions that enter and remain in the steel through the above-mentioned channels appear occasionally in the steel ingot. They are generally large in size and often appear on the surface of the steel ingot. In order to remove the dissolved oxygen in the steel to the greatest extent and make the generated deoxidized products be discharged from the steel smoothly, an appropriate deoxidation method must be adopted.

Contact Us

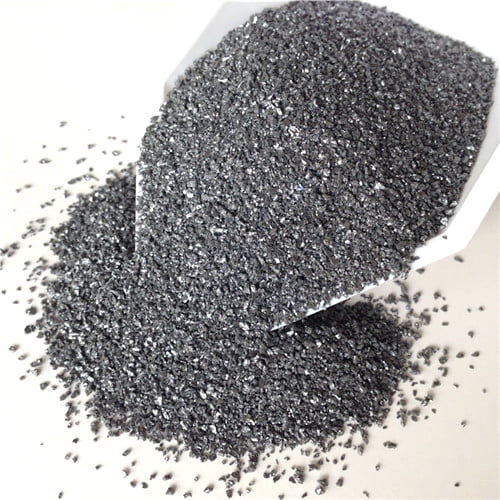

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China