NEWS

The Role of Silicon Metal in the Aluminum Recycling Process Industry

Silicon metal plays an important role in the aluminum recycling industry. Aluminum recycling is an important process to reduce the environmental impact of mining and refining new aluminum. It is estimated that nearly 75 percent of the aluminum produced since its discovery in the 1800s is still in use today. The recycling of aluminum saves energy and reduces greenhouse gas emissions. This has been made possible by the development of silicon metal, which plays a key role in the recycling process.

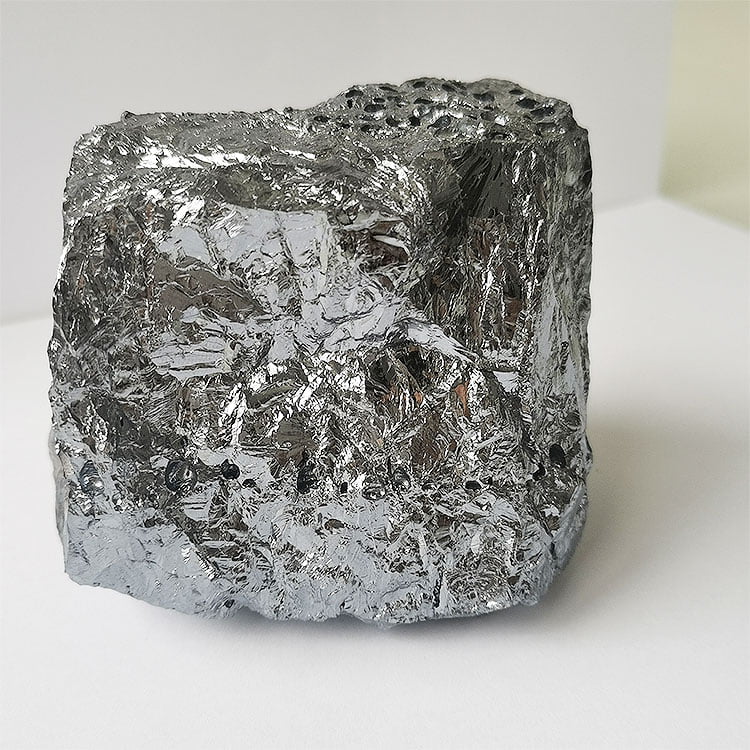

Silicon metal is a crucial alloying agent in the production of aluminum alloys. It is added to aluminum to improve its properties, including strength, ductility, and corrosion resistance. Aluminum alloys with silicon are commonly used in the automotive industry, aerospace industry, and other manufacturing processes. Silicon is also used in the production of aluminum ingots, which are used as feedstock for aluminum products.

Silicon is added to aluminum through the process of alloying. The process involves melting aluminum scrap and adding other elements, including silicon, to improve the properties of the metal. The addition of silicon increases the strength and corrosion resistance of the aluminum, making it more durable and suitable for use in various applications.

In the aluminum recycling industry, silicon metal is an important additive in the production of aluminum alloys. The use of silicon in the recycling process reduces the need for new aluminum, thereby reducing energy consumption and greenhouse gas emissions. By using recycled aluminum with silicon, manufacturers can reduce the environmental impact of their production processes while still maintaining the quality and reliability of their products.

Silicon metal is also used in the production of aluminum ingots. It is added to aluminum scrap during the melting process, resulting in the production of high-quality ingots. These ingots are then used as raw material for the production of aluminum products, including sheets, rods, and other products.

In addition to its role in the aluminum recycling industry, silicon metal is also used in the production of other materials. It is used in the production of solar panels, which are becoming increasingly important as a source of renewable energy. Silicon is also used in the production of semiconductors, which are used in electronic devices such as computers, smartphones, and other devices.

The use of silicon metal in the aluminum recycling industry has significant benefits for the environment. Recycling aluminum reduces the need for mining and refining new aluminum, which is a labor-intensive and environmentally damaging process. The use of recycled aluminum with silicon reduces energy consumption and greenhouse gas emissions, which are major contributors to climate change.

Silicon metal plays a crucial role in the aluminum recycling industry. It is added to aluminum scrap during the melting process to produce high-quality aluminum alloys and ingots. The use of recycled aluminum with silicon reduces the environmental impact

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China