NEWS

The Role of Silicon Metal Particle Size in Aluminum Production, Automobile Parts, and Beyond

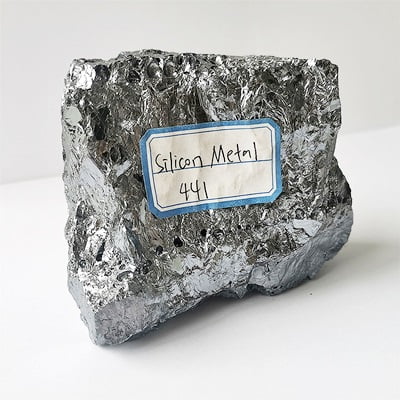

Silicon metal plays a significant role in various industries, including aluminum production, automobile manufacturing, and several other sectors. The size of silicon metal particles used in these industries has a direct impact on the performance and quality of the final products. In this article, we will discuss the importance of selecting the proper size of silicon metal for aluminum production, automobile parts manufacturing, and other industrial applications, highlighting the considerations and benefits associated with each industry.

Aluminum Production:

In aluminum production, silicon metal is added to the molten aluminum to improve its strength, fluidity, and castability. The appropriate size of silicon metal is crucial for achieving the desired properties in the final aluminum product. The selection of silicon metal size depends on factors such as the production method, desired alloy composition, and the specific application of the aluminum.

a. Foundry Industry:

In foundries, where aluminum castings are produced, silicon metal is usually used in larger sizes, such as lumps or coarse granules. These sizes allow for slower dissolution rates, ensuring controlled and uniform distribution of silicon throughout the molten aluminum. This leads to improved castability and reduced casting defects.

b. Aluminum Alloys:

For the production of aluminum alloys, silicon metal is often used in finer granule or powder form. Smaller particle sizes provide a larger surface area, facilitating rapid dissolution and homogenous distribution of silicon in the alloy matrix. This results in enhanced mechanical properties, improved corrosion resistance, and better performance in applications such as automotive parts and aerospace components.

Automobile Parts Production:

Silicon metal is widely utilized in the automobile industry for the manufacturing of engine blocks, cylinder heads, pistons, and other critical components. The appropriate size of silicon metal used in automobile parts production depends on several factors, including the alloy composition, casting process, and the desired mechanical properties of the parts.

a. Hypoeutectic Alloys:

In hypoeutectic aluminum-silicon alloys (containing silicon below the eutectic composition), finer sizes of silicon metal are commonly employed. These smaller particles aid in refining the microstructure, reducing the formation of undesirable phases, and improving the mechanical properties of the castings. Moreover, fine silicon particles enhance the wear resistance and thermal conductivity of the automobile parts.

b. Eutectic Alloys:

For eutectic aluminum-silicon alloys (having the eutectic composition), a combination of coarse and fine sizes of silicon metal is often used. Coarse particles act as nucleation sites for eutectic silicon growth, promoting a desirable dendritic microstructure. Fine particles aid in improving the mechanical properties, such as tensile strength and fatigue resistance.

Other Industrial Applications:

Silicon metal finds applications in various other industries, including electronics, solar energy, and construction. The size of silicon metal used in these industries depends on the specific requirements of the applications.

a. Electronics and Solar Energy:

In electronics and solar panel manufacturing, silicon metal powders with controlled particle sizes are commonly employed. Finer particle sizes enable better control over the deposition process, ensuring uniform coatings and precise electrical properties in semiconductor devices and solar cells.

b. Construction Industry:

In the construction industry, silicon metal is used as an additive in concrete and cement. Coarse granules or lumps are generally preferred to enhance the strength, durability, and resistance to chemical attacks in structures.

Choosing the appropriate size of silicon metal is crucial for achieving optimal performance and quality in aluminum production, automobile parts manufacturing, and other industrial applications. The size selection depends on factors such as the production method, desired alloy composition, and specific application requirements

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China