NEWS

Trade-Offs: Choosing Between High Purity and Cost-Effective Silicon Metal Grades

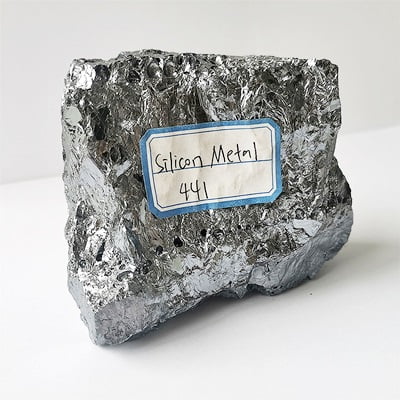

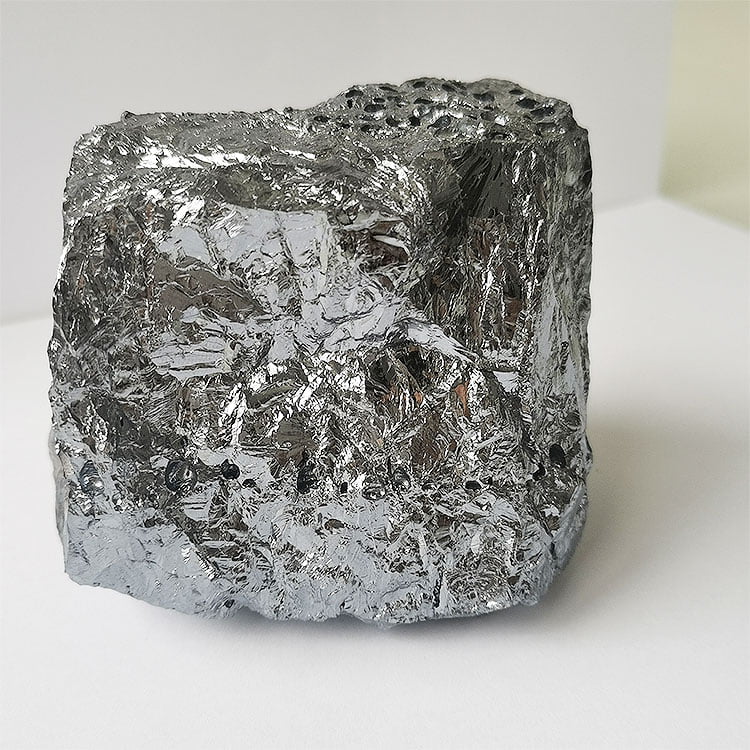

While it is true that silicon metal 97 is typically considered a lower quality grade compared to silicon metal 553 and 441 due to its lower silicon content and higher impurity levels, there are still some applications where it can be a suitable choice.

Silicon metal 97 can potentially replace silicon metal 553 and 441 in some applications, but it depends on the specific requirements and performance characteristics of the final product.

Silicon metal 97 is typically considered a lower quality grade compared to silicon metal 553 and 441 due to its lower silicon content and higher impurity levels. As a result, it may not be suitable for applications where high purity silicon is required, such as in the electronics industry where silicon is used to make semiconductors and solar cells.

However, silicon metal 97 may be a suitable replacement for silicon metal 553 and 441 in certain applications where lower purity silicon is acceptable,

One reason why some people may still buy silicon metal 97 is because it is often less expensive compared to higher purity grades of silicon metal such as 553 and 441. This can make it a more cost-effective choice for certain applications where high purity silicon is not required.

In addition, some industries may have specifications or requirements that allow for the use of lower purity silicon metal, and silicon metal 97 may meet those specifications at a lower cost compared to higher purity grades. For example, in the production of some chemicals or alloys, the impurities present in silicon metal 97 may not be a concern, and the lower cost may make it a more viable choice.

Overall, while silicon metal 97 may not be as high quality as silicon metal 553 and 441, there are still some applications where it can be a suitable choice due to its lower cost and acceptable level of purity.

Aluminum smelters use silicon metal as a reducing agent to remove oxygen from the alumina during the production of aluminum. The silicon reacts with the oxygen to form silicon dioxide, which is then removed as a slag. This process helps to purify the aluminum and improve its quality. Additionally, the use of silicon metal can help to reduce energy consumption and increase efficiency in the smelting process.

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China