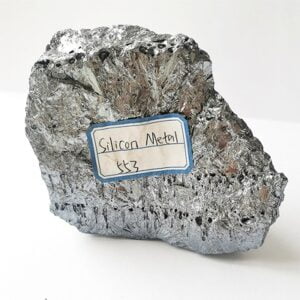

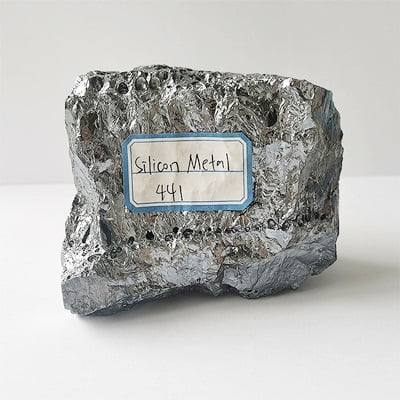

The surging demand for solar panels is a significant driver of the silicon metal market. Silicon, the most common semiconductor material in solar cells, accounts for approximately 95% of modules sold today. Refiners turn metallurgical-grade silicon into high-purity silicon for use in semiconductors and solar cells. Consequently, manufacturers can use it in the production of solar panels.

The solar industry is one of the fastest-growing industries globally. The energy sector adds most of the world’s new power capacity, says the International Energy Agency (IEA).

The IEA forecasts a 50% increase in renewable electricity generation capacity between 2019 and 2023, primarily driven by solar photovoltaics (PV). Experts expect solar PV to account for nearly 60% of the projected increase.

In 2017, solar power accounted for more than half of the world’s renewable electricity. By 2022, this percentage had increased to almost 60%. The addition of 188.6 GW of solar power capacity accompanied this increase.

In 2020, COVID-19 caused a major slowdown in projects. In 2020, COVID-19 slowed down many projects.

If India, Brazil, and South Africa continue to grow their solar energy, it could reach 197.3 GW. This amount would be about 62.3% of the world’s renewable energy supply.

India will double its solar power capacity by 2022 as new utility projects come online.

In the US, the 26% ITC extension will boost capacity additions in 2022, making projects more financially appealing. In 2022, about 30% of solar growth in the US will come from distributed solar PV due to cost reductions and tax credits.

In the third quarter of 2021, the US added 5.4 GW of solar power, a 33% increase from the same period in 2020. Texas and Virginia made up over half of the large solar installations in the third quarter of both 2020 and 2021.

In 2021, solar power generated 54% of US electricity from January to September, up from 44% in 2020. Supply chain constraints and rising raw material prices are expected to have a negative impact on the market in 2022.

According to the Ministry of New and Renewable Energy (MNRE), India ranked fourth globally in solar PV deployment at the end of 2021. As of November 30, 2022, the installed solar capacity reached approximately 61.97 GW. India has achieved grid parity with highly competitive solar tariffs.

The aforementioned developments are expected to drive the silicon metal market for the solar industry during the forecast period.

![]()