NEWS

The Application of Low Carbon Ferrochrome in Steelmaking Industry

Low carbon ferrochrome is an iron alloy composed of iron and silicon. Low-carbon ferrochromium is an iron-silicon alloy made of coke, steel shavings and quartz as raw materials and smelted in an electric furnace. Because silicon and oxygen are easily combined into silicon dioxide, low-carbon ferrochromium is often used as a deoxidizer in steelmaking. At the same time, because SiO2 generates a lot of heat, it is also beneficial to increase the temperature of molten steel during deoxidation. At the same time, low-carbon ferrochromium can also be used as an alloying element additive, and is widely used in low-alloy structural steel, spring steel, bearing steel, heat-resistant steel and electrical silicon steel. Low-carbon ferrochromium is commonly used as a reducing agent in ferroalloy production and chemical industry.

Low carnon ferro chrome is also used as deoxidizer and alloying agent in steelmaking industry. In order to obtain steel with qualified chemical composition and ensure the quality of steel, adding a certain amount of silicon to steel can significantly improve the strength, hardness and elasticity of steel. Steel (containing SiO.30-1.8%), spring steel (containing SiO.40-2.8%) and silicon steel for transformers (containing silicon 2.81-4.8%) also use low-carbon ferrochrome as an alloying agent. Practice has proved that low-carbon ferrochromium not only meets the deoxidation requirements of steelmaking, but also has desulfurization performance and has the advantages of large specific weight and strong penetrating power.

In addition, in the steelmaking industry, low-carbon ferrochromium powder is often used as a heating agent for steel ingot caps to improve the quality and recovery rate of steel ingots by utilizing the characteristic that low-carbon ferrochromium powder can release a large amount of heat when it is burned at high temperature.

Contact Us

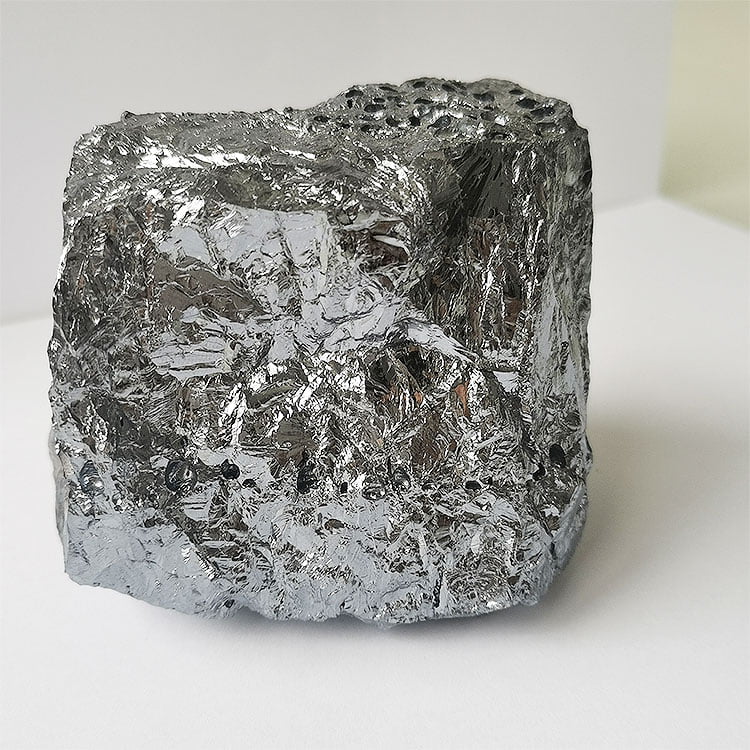

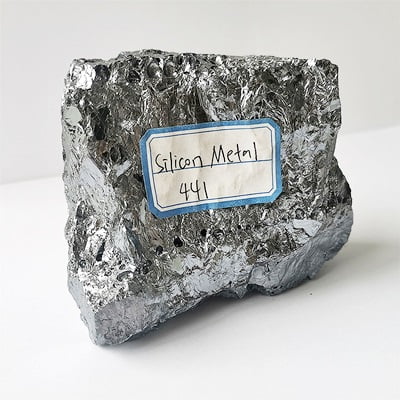

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China