NEWS

Application and Difference of Ferrosilicon and FeSi Grains

Ferrosilicon is a ferroalloy composed of iron and silicon. It is made of coke, steel shavings, quartz (or silica) and smelted in an electric furnace.

Ferro Silicon Applications

1. Ferrosilicon is an important deoxidizer in the steelmaking industry. Ferrosilicon is usually used for precipitation deoxidation and diffusion deoxidation. Brick iron is also used as an alloying agent in steelmaking.

2. Ferro silicon is also used as an inoculant and nodulizer in the casting industry. In the production of ductile iron, 75 ferrosilicon is an important inoculant (to help precipitate graphite) and nodularizer.

3. Ferroslicon is also a reducing agent in the production of ferroalloys. Not only the chemical affinity between silicon and oxygen is great, but also the carbon content of high silicon ferrosilicon is very low. Therefore, high-silicon ferrosilicon (or silicon alloy) is a reducing agent commonly used in the production of low-carbon ferroalloys in the ferroalloy industry.

Ferrosilicon grains are formed by crushing ferrosilicon into small pieces of a certain proportion and sieving through a sieve with a certain number of meshes. The small grains screened out are currently used as inoculants for foundries in the market.

Regular granularity of ferrosilicon grains: 0.2-1mm, 1-3mm, 3-8mm, or customized according to customer requirements.

Advantages of Ferrosilicon Grains:

Ferrosilicon grains can not only be used in the steelmaking industry but also a metallurgical material commonly used in the iron casting industry. This is mainly because ferrosilicon grains can be used to replace inoculants and nodularizers. In the cast iron industry, the price of ferrosilicon grains is far Lower than steel, and more easily melted, are castable ferroalloy products.

Contact Us

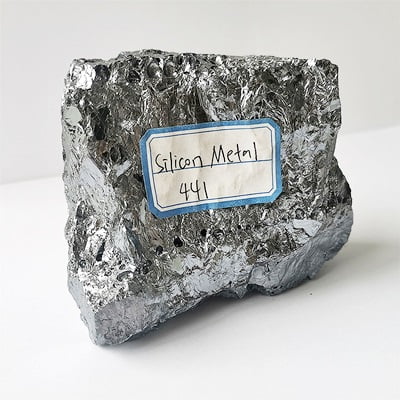

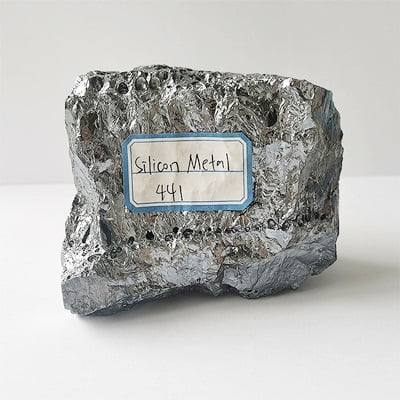

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China