Silicon Carbide

Silicon Carbide Introduction

Silicon carbide deoxidizer can improve steel strength and toughness, it quickly deoxidize, greatly reduce smelting cost, stabilize the quality of molten iron, and delay the hatching and reduction time of molten iron.

Silicon carbide deoxidizer can replace the more expensive traditional deoxidizer ferrosilicon powder and alloy powder. It is suitable for deoxidation during smelting of general steel, alloy steel and special steel. With the advantage of rich foam, it can also effectively improve recovery rate. The use of silicon carbide as a steelmaking deoxidizer can stabilize the quality of molten steel, and has the effect of refining the particles of molten steel and removing harmful impurities. After use, the casting temperature of molten steel is high and the quality of casting slabs is excellent.

Features of Silicon Carbide

- Compared with ferrosilicon powder, carbon powder and calcium carbide, silicon carbide's oxygen reaction can shorten the reduction time, reduce power consumption and improve labor productivity.

- The decomposition and oxidation of silicon carbide deoxidizer at high temperature is an exothermic reaction process, and the positive pressure in the furnace is strong, which can ensure the necessary conditions for deoxidation and sulfur removal and reduce the sulfur content.

- By shortening the reduction period, the probability of sucking molten metal at the rear is lowered and the quality of molten metal is secured.

- Reduce the amount of quicklime and fluorite powder added, reduce cost, reduce harmful gas concentration and dust pollution, help improve working conditions.

- The foam slag is rich and active, and at the same time, the bubble wraps the arc yellow to reduce the arc radiation, thereby improving the life of the furnace lining and the furnace cover, reducing the heat shutdown time and the consumption of auxiliary materials.

Contact Us to Get Your Best Price !

Silicon Carbide Technical Specifications

| Grade | Chemical Component | |||

| Sic | F.C | Fe2O3 | ||

| SIC A | ≥98.60% | ≤0.20% | 0.40% | |

| SIC B | ≥95.50% | ≤0.50% | 0.70% | |

| ≥90.00% | ≤1% | 1.2% | ||

| SIC C | 75.00%-80.00% | 2.50%-3.50% | 3% | |

Get in Touch

Qugou Industrial Zone

Anyang City, Henan Province of China

Phone : + 86 159 37282819

Email : info@jbtmetals.com

MON-FRI 09:00 – 19:00

SAT-SUN 10:00 – 14:00

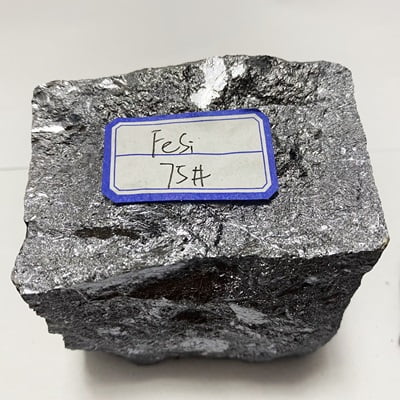

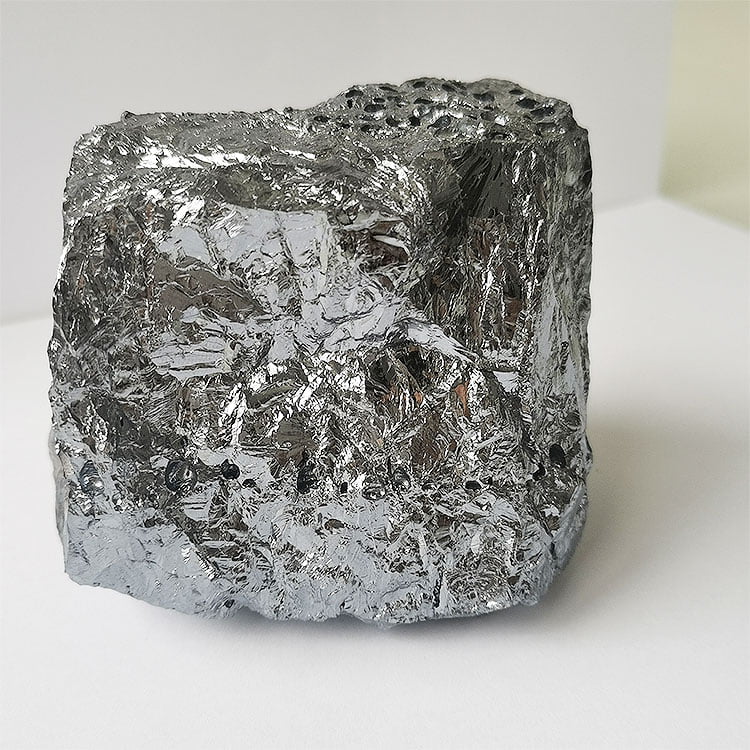

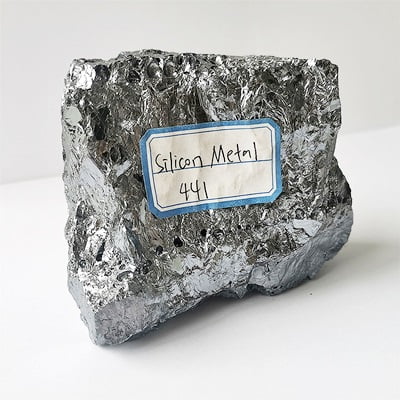

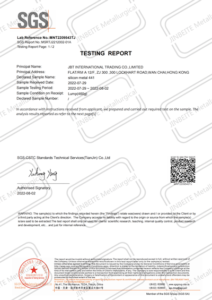

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032026

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China