NEWS

Analyzing Recent Trends in the Silicon Metal Market

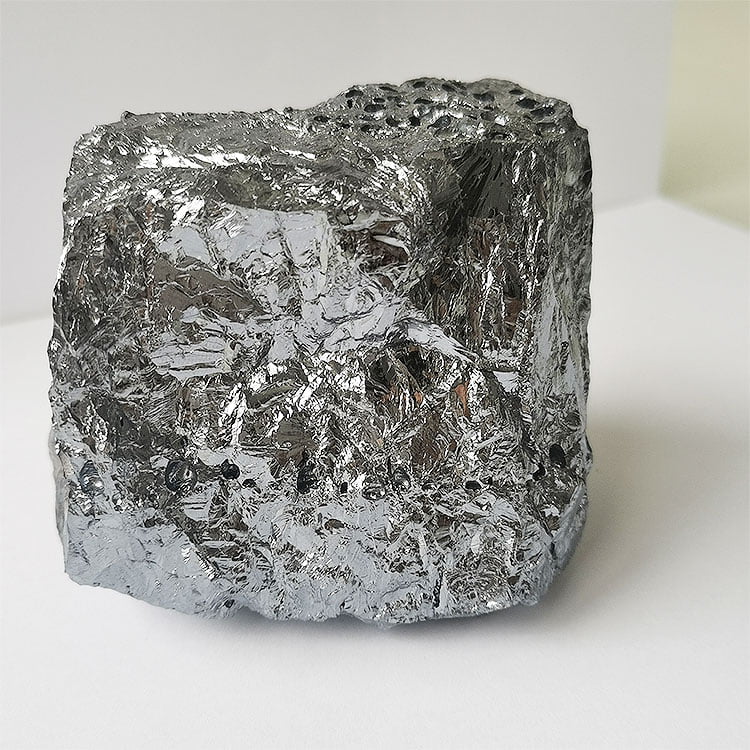

In recent months, the silicon metal market has experienced significant price fluctuations. The price of silicon metal, which is a critical component in many industrial applications, has been on a rollercoaster ride in the past year. In this article, we will analyze the recent price trends and provide an outlook on the future price of silicon metal.

The global demand for silicon metal has been on the rise in recent years due to its extensive use in the production of aluminum alloys, silicones, and semiconductors. However, the COVID-19 pandemic has disrupted supply chains and caused a sharp decline in demand for many industrial products, including silicon metal. As a result, the price of silicon metal dropped significantly in the first half of 2020.

However, the market started to recover in the second half of 2020 as demand for aluminum alloys and semiconductors picked up. The increasing demand for electric vehicles and solar panels also contributed to the recovery of the silicon metal market. As a result, the price of silicon metal increased by more than 50% from its lowest point in 2020.

The upward trend continued into 2021, with prices reaching an all-time high in February. However, the market started to cool down in April as supply chain issues and logistical challenges caused a slowdown in demand. The price of silicon metal dropped by more than 10% from its peak in February.

Looking ahead, the future of the silicon metal market is uncertain. On one hand, the increasing demand for electric vehicles and solar panels is expected to drive the demand for silicon metal in the coming years. The global shift towards renewable energy sources is also expected to boost demand for silicon metal. On the other hand, supply chain issues and logistical challenges may continue to cause disruptions in the market.

Another factor that may affect the future price of silicon metal is the increasing competition from alternative materials such as gallium nitride and silicon carbide. These materials are seen as potential replacements for silicon metal in some applications, which could reduce the demand for silicon metal.

The silicon metal market has experienced significant price fluctuations in recent months due to the COVID-19 pandemic and supply chain disruptions. While the future of the market is uncertain, the increasing demand for electric vehicles and solar panels is expected to drive the demand for silicon metal in the coming years. However, supply chain issues and competition from alternative materials may continue to affect the price of silicon metal in the future.

You May Like to Learn More...

Contact Us

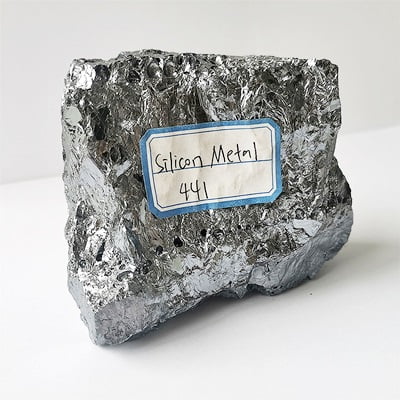

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China