NEWS

Ferro Silicon, Carbon Raiser, Inoculants, Nodulizer, Deoxidizer for Casting

Adding ferro silicon, carbon raiser, inoculants, nodulizer, deoxidizer, and other alloying agents in casting. These agents are added to the molten metal to improve its properties, such as strength, ductility, and machinability.

The steps for adding alloying agents may vary depending on the specific casting process being used. However, the general steps involved are as follows:

Determine the required amount of alloying agent: The amount of alloying agent required depends on the type of alloy being produced and the desired properties of the final product. The amount of alloying agent is usually calculated based on the weight or volume of the molten metal.

Prepare the alloying agent: The alloying agent is prepared by crushing, grinding, or melting it into a suitable form for addition to the molten metal. For example, ferro silicon is often crushed into small pieces, while deoxidizers and nodulizers are usually in the form of powder or granules.

Add the alloying agent to the molten metal: The alloying agent is added to the molten metal using a ladle or other suitable method. The agent is typically added in small amounts and stirred into the molten metal to ensure proper mixing.

Wait for the alloying agent to dissolve: The alloying agent needs to dissolve completely in the molten metal before it can have an effect on the final product. The time required for dissolution varies depending on the type of agent and the temperature of the molten metal.

Add other alloying agents: Other alloying agents, such as carbon raiser or inoculants, may be added after the initial alloying agent has dissolved. The order of addition is important and depends on the type of alloy being produced.

Allow the metal to solidify: Once all of the alloying agents have been added and properly mixed, the molten metal is allowed to cool and solidify. This process can take several hours or more depending on the size and complexity of the casting.

Overall, the process of adding alloying agents in casting requires careful planning and execution to ensure that the final product has the desired properties. The steps involved may vary depending on the specific alloy being produced and the casting process being used. It is important to follow the appropriate safety precautions when handling and adding alloying agents to the molten metal.

You May Like to Learn More...

Contact Us

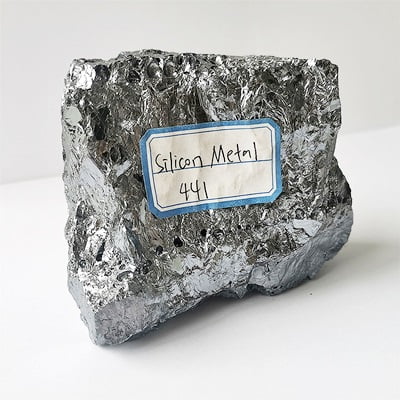

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China