NEWS

Innovations in Silicon Metal Refining for Solar Energy

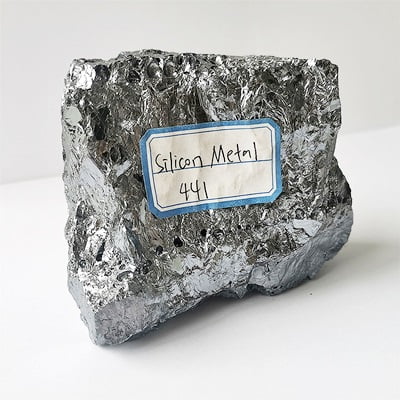

Silicon metal is a critical material used in the solar industry. It is used to produce solar panels, which are the primary component of solar energy systems. The demand for silicon metal has grown significantly in recent years as more people and businesses are turning to solar energy as a cleaner and more sustainable source of power.

Silicon is one of the most abundant elements on earth, but it is not found in its pure form. It is typically found in combination with other elements, such as oxygen, in minerals like quartz and sand. To produce silicon metal for use in the solar industry, the mineral must be refined and purified.

The process of refining silicon metal involves several steps. First, the mineral is crushed and ground into a fine powder. Next, it is mixed with a reducing agent, such as carbon, and heated in a furnace to produce a chemical reaction. This process separates the silicon from the other elements in the mineral, producing pure silicon metal.

The quality of the silicon metal produced is critical for use in the solar industry. The purity level must be at least 99.999%, and it must be free of impurities like iron, aluminum, and other metals that can affect the performance of solar panels. The silicon metal must also be produced in large quantities to meet the growing demand for solar energy systems.

The solar industry is a major consumer of silicon metal. The production of solar panels accounts for more than 80% of the demand for silicon metal worldwide. The amount of silicon metal required for each panel varies depending on the type and size of the panel, but it typically ranges from 4 to 8 grams per watt of power output.

The demand for silicon metal in the solar industry has grown significantly in recent years. According to a report by Allied Market Research, the global market for silicon metal was valued at 6.2 billion in 2019 and is expected to reach 6.2billionin2019andisexpectedtoreach8.6 billion by 2027. The report attributes this growth to the increasing demand for solar energy systems, particularly in developing countries.

The production of silicon metal for use in the solar industry has several environmental impacts. The refining process requires significant amounts of energy, which contributes to greenhouse gas emissions and climate change. The mining of quartz and sand can also have negative environmental impacts, such as habitat destruction and water pollution.

Efforts are underway to reduce the environmental impact of producing silicon metal for use in the solar industry. One approach is to develop new refining processes that use renewable energy sources like solar or wind power. Another approach is to develop new materials that can replace silicon in solar panels, such as perovskite or organic photovoltaics.

In conclusion, silicon metal is a critical material used in the production of solar panels for the solar energy industry. The demand for silicon metal has grown significantly in recent years as more people and businesses turn to solar energy as a cleaner and more sustainable source of power. While the production of silicon metal has environmental impacts, efforts are underway to reduce these impacts through new refining processes and alternative materials.

You May Like to Learn More...

Contact Us

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China