Silicon metal and ferro silicon are both important materials in the metallurgical industry, but they have distinct differences in terms of composition, production, and applications.

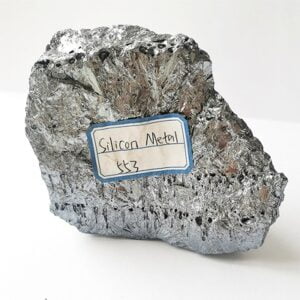

Silicon Metal

Composition and Production:

Silicon metal is primarily composed of silicon (typically 98-99% pure silicon).

It is produced by the reduction of high-purity quartz in electric arc furnaces using carbon electrodes.

The typical grades of silicon metal are categorized by their purity levels, such as 553#, 441, 3303, and 2202, indicating the maximum allowable impurity content.

Applications:

Aluminum Alloys: Used to improve the strength and durability of aluminum alloys.

Semiconductors: Due to its high purity, it is used in the production of semiconductors for electronics.

Silicones and Silanes: Used as a raw material for silicones and silanes, which are essential in various industrial applications.

Solar Panels: Silicon metal is a crucial component in the manufacturing of photovoltaic cells for solar panels.

Ferro Silicon

Composition and Production:

Ferro silicon is an alloy of iron and silicon, typically containing 15-90% silicon by weight.

It is produced in submerged arc furnaces by reducing silica or sand with coke in the presence of iron.

Common grades include ferro silicon 75 and ferro silicon 90, where the number indicates the approximate percentage of silicon content.

Applications:

Steel Production: Used as a deoxidizer and alloying agent in steelmaking to improve the strength and quality of steel.

Cast Iron: Added to cast iron to improve its hardness and wear resistance.

Manufacture of Silicon Steel: Used in the production of silicon steel for transformer cores and electrical appliances.

Other Alloys: Serves as an important ingredient in the production of various ferrous and non-ferrous alloys.

Key Differences

Composition: Silicon metal is nearly pure silicon, whereas ferro silicon is an alloy of iron and silicon.

Production Process: Silicon metal is produced by reducing quartz with carbon in an electric arc furnace, while ferro silicon is made by reducing silica with coke in the presence of iron in a submerged arc furnace.

Applications: Silicon metal is primarily used in aluminum alloys, semiconductors, silicones, and solar cells, whereas ferro silicon is used as a deoxidizer and alloying agent in steelmaking, cast iron production, and silicon steel manufacturing.