NEWS

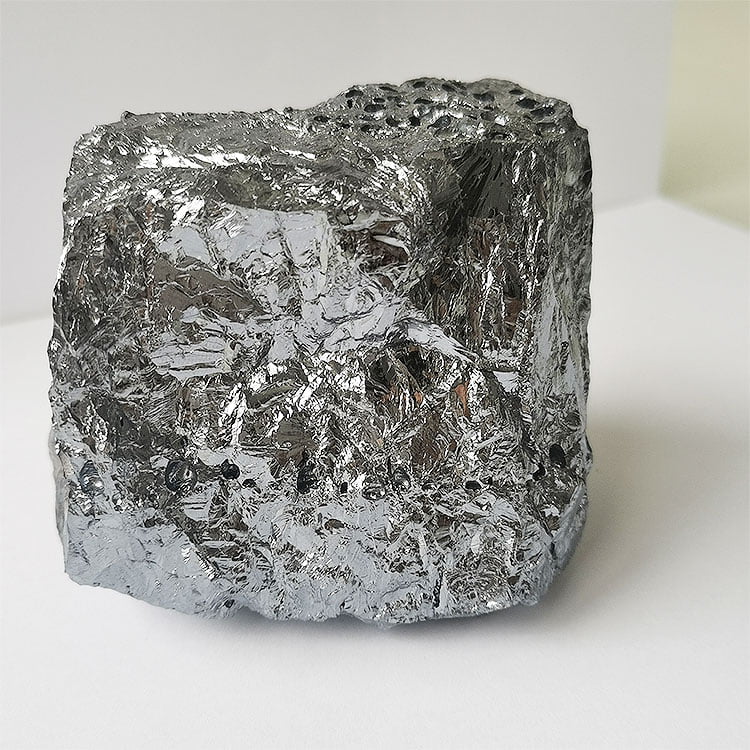

How to Determine the Silicon Content in Silicon Metal?

Determining the silicon content in silicon metal is an important process in the production of silicon-based products. There are several methods for determining silicon content in silicon metal, including the gravimetric method, the colorimetric method, and the X-ray fluorescence method.

The gravimetric method involves dissolving the silicon metal sample in acid and then precipitating the silicon as silicon dioxide. The silicon dioxide is then weighed, and the amount of silicon in the sample is calculated based on the weight of the silicon dioxide. This method is accurate but time-consuming.

The colorimetric method involves reacting the silicon metal sample with a reagent that produces a colored compound. The intensity of the color is proportional to the amount of silicon in the sample, and this can be measured using a spectrophotometer. This method is faster than the gravimetric method but may not be as accurate.

The X-ray fluorescence method involves bombarding the silicon metal sample with X-rays and measuring the resulting fluorescence. The intensity of the fluorescence is proportional to the amount of silicon in the sample, and this can be used to calculate the silicon content. This method is fast and non-destructive but may require expensive equipment.

In conclusion, determining the silicon content in silicon metal can be done using several methods, each with its advantages and disadvantages. The choice of method will depend on factors such as accuracy requirements, time constraints, and availability of equipment.

You May Like to Learn More...

Contact Us

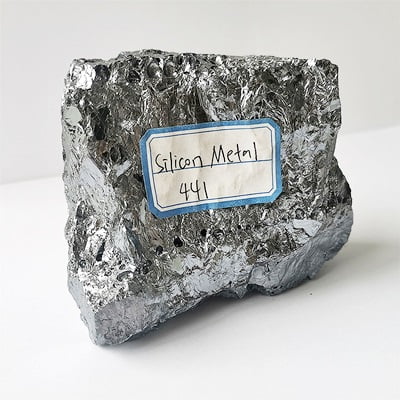

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China