NEWS

The Importance of Properly Sized Silicon Carbide in Molten Steel

Silicon carbide (SiC) is a popular additive used in the steelmaking process to improve the mechanical properties of steel. The proper size of SiC to be added to molten steel depends on the desired final composition and properties of the steel. Typically, SiC particles with a size range of 3-5 mm are added to molten steel.

The size of the SiC particles affects the degree of improvement in the mechanical properties of the steel. SiC is known for its hardness, wear resistance, and toughness, which can be transferred to the steel during the casting process. The 3-5 mm size range is commonly used because it provides a good balance between improving the mechanical properties and maintaining the desired steel composition.

One of the primary reasons for adding SiC to molten steel is to improve its wear resistance. SiC is a very hard material, with a Mohs hardness of 9.5, which is second only to diamond. The addition of SiC to molten steel can significantly increase its wear resistance, making it more suitable for use in applications where it will be subjected to high levels of wear and tear. The 3-5 mm size range is preferred because it provides a good balance between wear resistance and maintaining the desired steel composition.

The addition of SiC to molten steel can also help to reduce the amount of energy required during the casting process. SiC has a high melting point, which means it can withstand high temperatures without melting. This property allows it to act as a refractory material, which helps to insulate the molten steel and reduce heat loss during the casting process. By reducing heat loss, less energy is required to maintain the desired temperature of the molten steel.

The size of the SiC particles can also affect the efficiency of mixing and distribution in the molten steel. SiC particles that are too small may clump together, leading to uneven distribution and reduced effectiveness of the additive. On the other hand, particles that are too large may sink to the bottom of the molten steel and not mix properly. The 3-5 mm size range is preferred because it provides a good balance between efficient mixing and distribution.

In conclusion, SiC is a popular additive used in the steelmaking process to improve wear resistance, thermal conductivity, and energy efficiency. The proper size of SiC to be added to molten steel depends on the desired final composition and properties of the steel. Typically, SiC particles with a size range of 3-5 mm are added to molten steel because it provides a good balance between improving mechanical properties, thermal conductivity, and efficient mixing and distribution.

You May Like to Learn More...

Contact Us

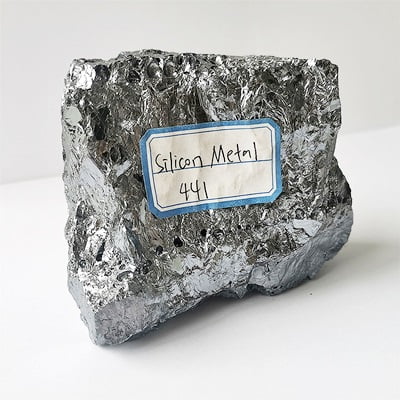

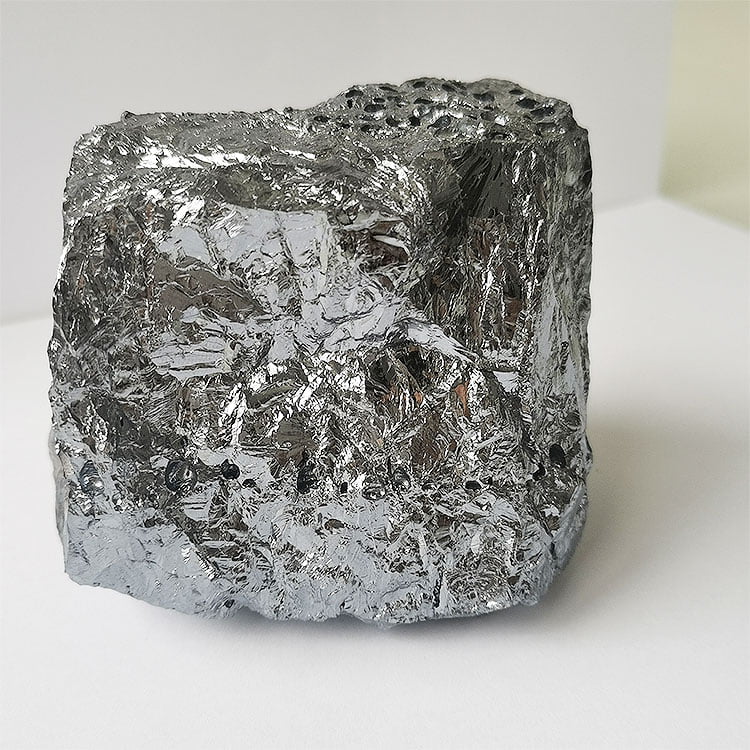

JBT produces and supplies silicon metal and ferrosilicon products, mainly products are silicon metal 553, 441, 421, 411 3303,2202, 97, silicon carbide, carbon raiser for steelmaking and casting industries. We also make electrolytic manganese metal, inoculants and nodulizers.

Get in Touch

- info@jbtmetals.com

- +86-372-5032025

- +86-15937282819

- Send Inquiry

- Online Chat

- Qugou Town, Anyang City, Henan Province of China